Web offset printing presses stretch thin films during the printing process; the films behave like a rubber band that has been pulled tight. Muller Martini has now developed StretchCorrectTM to ensure that the printing image is the correct length. Thanks to this new package, the Alprinta V web offset printing press guarantees that the printing image is the correct length, even for materials with variable elasticity.

Web offset printing presses stretch thin films during the printing process; the films behave like a rubber band that has been pulled tight. Muller Martini has now developed StretchCorrectTM to ensure that the printing image is the correct length. Thanks to this new package, the Alprinta V web offset printing press guarantees that the printing image is the correct length, even for materials with variable elasticity.

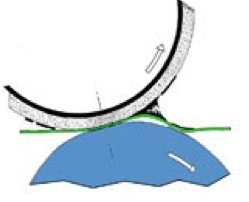

Offset printing technology has many advantages that are especially relevant for small and medium size runs, including a short time to market during platemaking, low plate costs, and a highly standardized printing process. In comparison with the printing processes that dominate package printing today, such as intaglio gravure and flexography, inks used in the offset printing process have a significantly higher tack value, which results in the ink being more resistant to decomposition in the printing gap. The ink tries to climb up the web on the rubber blanket (see photo). The stickiness, or tack, of the offset printing ink is responsible for this effect. Web tension control must be applied in web offset printing presses in order to counteract the effect. Unwanted Elastic Stretching

Unwanted Elastic Stretching

Extremely thin films are stretched in the web offset printing press and behave like a rubber band that has been pulled tight. When an image is printed onto the stretched film, the image is the correct length when the film is in its stretched state. When the product leaves the press, the printed image appears too short because the material is no longer stretched – the film has returned to its original length and the image along with it. However, for most products it is crucial that the length of the printed image on the finished product matches the specification exactly. Thanks to the new StretchCorrectTM package from Muller Martini, the Alprinta V web offset printing press now guarantees that the printed image is the correct length, even for materials with highly variable elasticity, using a single format set for a wide variety of products.

While the gear-driven back-up, blanket and plate cylinders of traditional offset printing presses always run at the same peripheral speed, the carbon-fiber blanket and plate cylinders on the Alprinta V are driven by an additional servo drive without the need for formatting or change wheels, allowing the length of the printed image to be modified without impacting quality. For some units, it may also be necessary to change the width of the printed image as well as the length. The various priorities within a printing press, resulting from the different ink supplies for individual units or different configurations of draw rollers, can cause the material web to be stretched unevenly in places. StretchCorrectTM allows the operator to correct deviations easily, enabling web offset printing to penetrate new market segments.