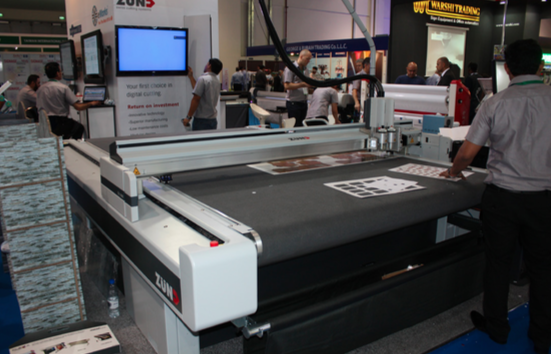

At ColourByte's booth the G3 Zund cutting system can be seen. The solution from the Swiss manufacturer, distributed by ColourByte, features – depending upon versioning – manual, semi-automated or fully automated production capabilities.

At ColourByte's booth the G3 Zund cutting system can be seen. The solution from the Swiss manufacturer, distributed by ColourByte, features – depending upon versioning – manual, semi-automated or fully automated production capabilities.

For semi-automatic production a table extension at the front of the machine serves as off-load area while the extension at the back is used for loading sheeted materials and boards. Once loaded the material advances automatically in and out of the active cutting area.

The fully automated material loading and unloading feature is enabled by the Zund Board Handling system whereby the operator only has to bring and remove the to be cutted and cut boards to and from the stacker.

However, not only boards can be handled by the Zund G3: For handling of textiles the company offers a guide roll that facilitates trouble-free advances as well as a range of roll- off systems. Perfect tension is made possible by a sophisticated dancer system, thus delivering textiles and

other substrates prone to wrinkle crease or stretch, wrinkle-free onto the cutting surface. The center winder enables processing of rolls up to 100 kg.

The workstation features the company's Cut Center software that among others enables saving of job statistics and already includes a settings for a multitude of materials in various thicknesses. The cut queue calculates and estimated processing

time for each phase of production that is saved along with the cut data. In addition, the Zund G3 features quick and easy tool changeovers whereby up to three modules can be freely combined. Users can choose from a range of cutting tools such as universal, different routing and punching, electric or pneumatic oscillating, rotary, wheel knife, scoring cutting, V-cut, passepartout, kiss-cut, creasing or raster braille.