Suitable for security printing, high-quality film embossing (hot film/cold film), sheet-fed printing

Suitable for security printing, high-quality film embossing (hot film/cold film), sheet-fed printing- Free of pollutants and non-hazardous to health according to ISEGA certificate

- Guarantees a smooth printing process and minimum downtimes

ContiTech has brought something new to the market for printing securities, high-quality film embossing (hot film/cold film) and sheet-fed printing – an enhanced printing blanket with a cover layer made of tiny glass beads. The Black Pearl glass bead printing blanket is extremely resilient and durable, as well as antistatic and ISEGA-certified. It is manufactured at ContiTech Elastomer Coatings in Northeim and is sold via ContiTech sales to printing shops all over the world – with fast, reliable, and straightforward service.

Guarantees a smooth printing process and minimum downtimes: Area Manager Michael Simm introduces the enhanced printing blanket Black Pearl for printing securities, high-quality film embossing (hot film/cold film) and for sheet-fed printing

Whether it is hologram films for bank notes and certificates or embossed foils for high-quality Swiss chocolate: Instead of using printing ink in the hot embossing process, a thin plastic film is applied to the printing stock by means of pressure and heat. The printing blanket plays a crucial role in this. On the one hand, it must have an ink-repellent surface so that no printing ink is smeared on the printed sheet or other guide elements of the machine. On the other hand, the printing blanket must withstand enormous press forces of up to 60 tons and therefore requires very high mechanical stability.

Whether it is hologram films for bank notes and certificates or embossed foils for high-quality Swiss chocolate: Instead of using printing ink in the hot embossing process, a thin plastic film is applied to the printing stock by means of pressure and heat. The printing blanket plays a crucial role in this. On the one hand, it must have an ink-repellent surface so that no printing ink is smeared on the printed sheet or other guide elements of the machine. On the other hand, the printing blanket must withstand enormous press forces of up to 60 tons and therefore requires very high mechanical stability.

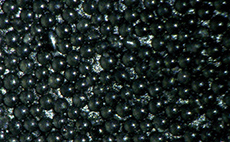

Firmly anchored: 7,000 glass beads per square centimetre

In this small, yet extremely fine, niche market, ContiTech is the only manufacturer worldwide that can produce a precision printing blanket of this quality class. "Glass is antistatic and is also a material with a very high surface hardness. This makes glass the number one material for this special field of application," explains Area Manager Michael Simm, responsible at ContiTech for the distribution of the new product. The secret lies in the extremely fine, uniform coating. Roughly 7,000 ultra-fine glass beads per square centimeter are anchored in the cover layer – each with the same exact diameter. The key is the completely uniform distribution of the glass beads and their special anchoring in the base.

Black Pearl is resistant not only to enormous embossing pressure but also to temperatures of up to 160 °C as well as all printing chemicals, benzine, acetone, and oil. And because packaging is a particularly sensitive issue in the foodstuffs industry, ContiTech has all printing blankets for the packaging industry inspected by an independent testing institute to ensure they meet food law requirements. As a result, Black Pearl has been awarded with the ISEGA certificate, which verifies that it is free of pollutants and non-hazardous to health.

"We ensure the dependability of our precision printing blanket in strict quality controls. The blanket is assembled in our in-house format center or at one of our partners," explains Simm, who puts the advantages of the blanket in a nutshell: "The Black Pearl guarantees a smooth hot or cold foil embossing process, and its high durability ensures minimum downtimes."

www.contitechde