Polyurethane instead of aluminium: successful new construction of a wastewater lifting plant

Polyurethane instead of aluminium: successful new construction of a wastewater lifting plant

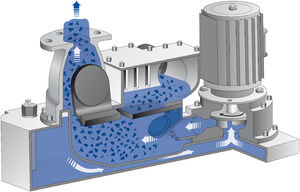

Half the weight, less noise, more cost-efficient production: The new series of wastewater lifting plants by manufacturer STRATE, Sarstedt, is, for the first time made of polyurethane (PUR). The solution developed by STRATE and THIEME was implemented by a functional plastic construction made of twelve formed parts at THIEME. The material and constructive advantages of PUR could be used consistently.

The fully automated type "AWALIFT" lifting systems of manufacturer STRATE have long been known and established in the wastewater area. THIEME's task was the development of a PUR construction for use in single- and two-family homes. It was to be based on the proven STRATE system's design, but much lighter and more cost-efficient as compared to the systems usually made of aluminium - the objective was cutting weight in half and clearly reducing production costs. The rough application conditions posed high demands to mechanical stability and chemical resistance.

"The material polyurethane enabled us to put all of our customer's requirements into practice", explains THIEME project manager Jürgen Vogel. All in all, eleven moulded and functional parts were produced from the highly resilient PUR material Baydur GS for the container and the sealing material collection space of the lifting system, the pump and the check valve; another part (the lift core) is made of low-density integral hard foam (Baydur 66 FR). The smallest PUR part weights 74 g, the largest 13.5 kg. The weight of all twelve parts together is 28.5 kg, about half of the previous aluminium construction. The entire lifting system of the new "AWALIFT 80" system, including pump motor, weighs approx. 42 kg - also much less than a comparable aluminium design (78 kg).

"The clear weight reduction is not the only advantage of this PUR construction," emphasises Jürgen Vogel. "Another important sales feature for the manufacturer is its low noise emission at start-up and during operation of the lifting system due to the low noise emission of the PUR parts." STRATE sales manager and authorised representative Wolf-Peter Strate sees this as a benefit, in particular over the polyethylene (PE) small lifting systems of other providers. "PE systems are often loud and tend to hum when the container is emptied. This is another benefit of our PUR construction." The sealing material collection space system developed by STRATE to protect the pumps from clogging could not have been implemented at all with PE components due to their lack of pressure resistance: "At full pump output, the pressure may rise up to 3 bar," says Strate. "We therefore knew that if we wanted a plastic solution, it had to be using PUR." Other benefits of the PUR design as compared to the previous cast-aluminium design are easier on-site installation and maintenance, higher flexibility and breaking resistance of the plastic, as well as the impact- and scratch-resistant surface.

Cost reduction by PUR-construction

The new PUR design also met all expectations regarding production and assembly costs - by the low tool costs of the PUR process, as well as by the option of integrating assembly components even during casting or foaming of the parts. Some threaded sleeves for screw-connections between formed parts were cast in, while at other places core bores were formed for permanent connection using self-cutting screws and sealing adhesive. This removes costs for mechanical finishing required for cast parts, such as drilling, turning or thread-cutting. Material-savings from the large wall thickness difference of 5 to 40 mm that becomes possible with PUR reduce costs greatly as well. Where possible, parts were designed with thin walls and reinforced with stiffening ribs in the required places. A positive "side-effect" of this construction is the low weight at high resilience.

The entire assembly is mounted in the Teningen THIEME-plant before it is completed with the functional parts of the pump and control and tested by STRATE.

www.thieme.eu